Chip Handling Solutions

We Next TECH CNC PVT LTD is authorise sales channel with U- Tech Associates (Bangalore) to provide customised coolant handling and filtration systems for wide varieties of metal machining and grinding applications.

At U TECH Associates we specialize in a variety of industries. We devote our time and resources to engineering products to meet the needs and exceed the expectations of our customers. We take pride in being the industry leaders with our advanced technology and team of experienced professionals leading the way.

By using our Bailing press, Briketto chip compactor and chip shredder metal chips and wastes shredded in mechanical industries can be recycled obtaining cylindrical briquettes of variable diameter (according to the briquetting press).

The 6 important advantages in briquetting:

1. SPACE SAVING: They allow a remarkable reduction of volumes (1/5-1/10 according to the type of material) if compared with the metal uncompressed chips and waste making the work environments much more organized and efficient. New stocking and production spaces will be available.

2. Reduction of recycling costs: They have a higher commercial value than the chips; In fact, the lower cost of transport of waste has a direct impact on net sales to collection centers. The briquetted waste could be a precious source of money.

3. Increase of the waste value: Dduring the melting phase, the briquettes sensibly increase their yield thanks to their peculiar feature to be compacted at very high pressures and therefore to have better qualities than simple chips which are directly in contact with the atmosphere and subject to oxidation, reduction and loss. Moreover, thanks to an oil percentage much lower than wet chips, needing a pre-treatment, they can be immediately loaded onto smelting furnaces and melting pots with an important reduction of time, a remarkable energy saving and the reduction of the risk of particle deposit on furnace and pot walls. It is important to notice the very high specific weight, about 80% of the original one, of the briquetted chip. Finally, work environments are cleaner and safer as briquetting metal powders (such as the magnesium) avoids the risk of self-ignitions and fires.

4. Reduction of freight costs: The waste transformation into briquettes improve the stocking handling and logistics so as to reduce the internal and external costs. The use of the forklift and consequently the time of the workers to the waste will be highly reduced.

5. Reduction of environmental impact: The briquettes can reduce the environmental impact due to the conditions and the status of containers or collection points , often not in good condition.

6. Reduction of environmental pollution: Thanks to the briquettes is possible to obtain a considerable reduction in the number of travel of the container, consequently more than 70% less fumes released into the atmosphere for the transport of the waste to collection centers.

For Chip Handling Solutions

Call @ 09416108449

Email @ sales.nextechcnc@gmail.com

We provides following Chip Handling Solutions

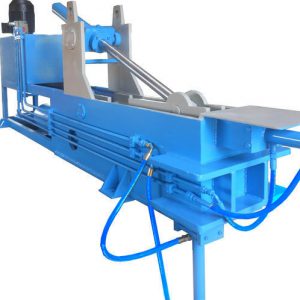

Baling Press

Spinetto Chip Centrifuge

Briketto Chip Compactor

Flytta Chip Conveyor

Scara Chip Shredder

Make an Enquiry

Fill the following form for Chip Handling Solutions: